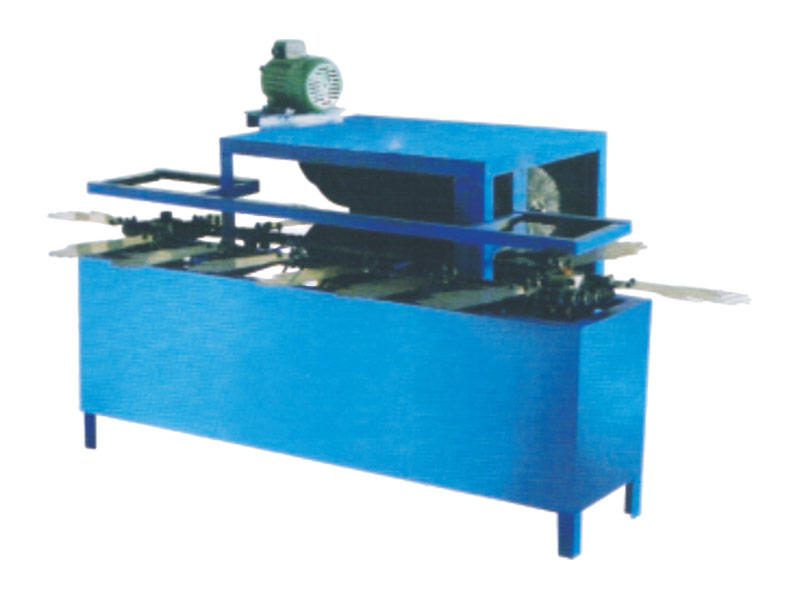

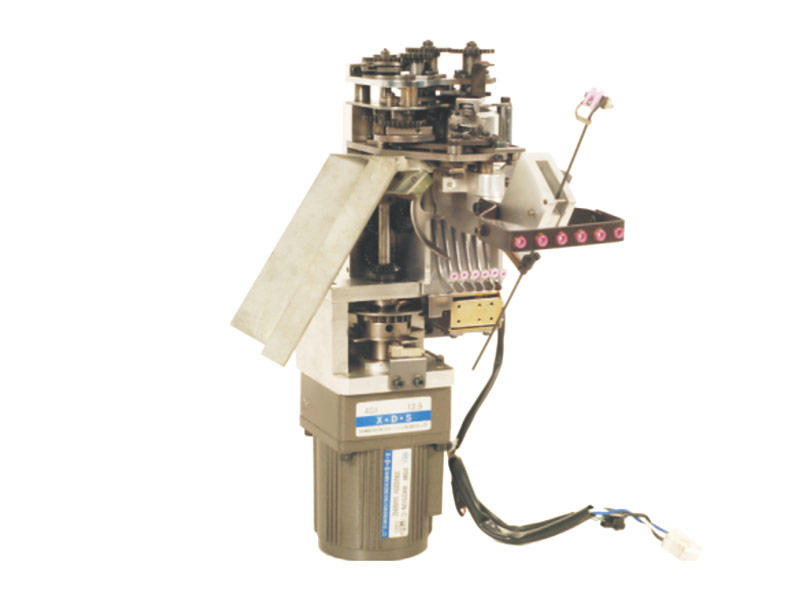

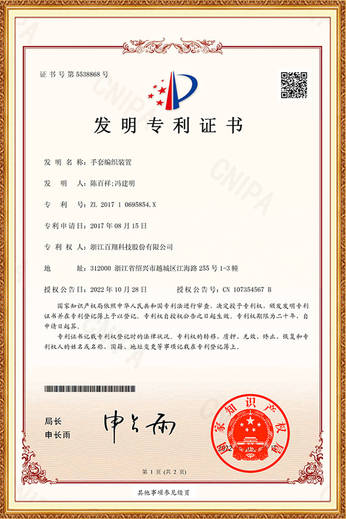

Features of Glove Machine Assistant Equipment:

The features of glove machine assistant equipment can vary depending on the specific type of equipment. However, here are some general features that are commonly found in different types of assistant equipment:

Automation: Many types of assistant equipment are designed to automate tasks that would otherwise need to be done manually, such as feeding yarn into the knitting machine or cutting the gloves into the desired shape. This helps to improve efficiency and reduce labor costs.

Precision: Assistant equipment is often designed to work with a high degree of precision, ensuring that the finished gloves meet the desired specifications for size, shape, and quality.

Versatility: Some types of assistant equipment can be used with a variety of different glove production machines, making them versatile and adaptable to a range of production needs.

Ease of use: Assistant equipment is often designed to be easy to use, with intuitive controls and simple set-up procedures.

Safety features: Many types of assistant equipment are designed with safety features, such as sensors and automatic shut-off mechanisms, to prevent accidents and injuries.

Maintenance and support: Reputable manufacturers of assistant equipment typically provide maintenance and support services to ensure that the equipment operates reliably and efficiently over its lifespan.

By choosing assistant equipment with these features, production facilities can improve the efficiency, quality, and safety of their glove production processes, ultimately leading to greater productivity and profitability.

Advantages of Glove Machine Assistant Equipment:

There are several advantages to using glove machine assistant equipment in the production of gloves, including:

Increased efficiency: Assistant equipment can automate tasks that would otherwise need to be done manually, reducing labor costs and increasing production efficiency.

Improved accuracy: Many types of assistant equipment are designed to work with a high degree of precision, ensuring that the finished gloves meet the desired specifications for size, shape, and quality.

Consistent quality: Assistant equipment can help to ensure consistent quality in the finished gloves, reducing the risk of defects or errors.

Versatility: Some types of assistant equipment can be used with a variety of different glove production machines, making them versatile and adaptable to a range of production needs.

Reduced waste: Assistant equipment can help to reduce waste by minimizing errors and defects in the production process.

Improved safety: Many types of assistant equipment are designed with safety features, such as sensors and automatic shut-off mechanisms, to prevent accidents and injuries.

Cost savings: By increasing efficiency and reducing waste, assistant equipment can help to reduce overall production costs and improve profitability.

Overall, the use of glove machine assistant equipment can help to improve the efficiency, quality, and safety of the glove production process, ultimately leading to greater productivity and profitability for production facilities.

中文简体

中文简体